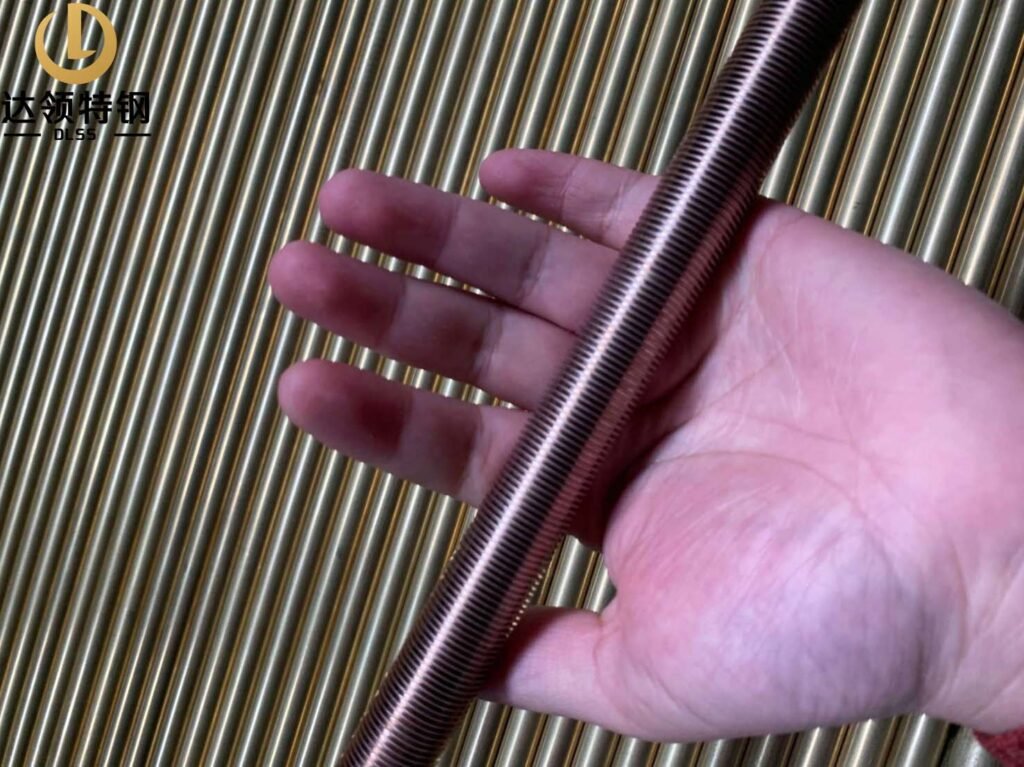

Copper Nickel ASTM B111 C70600(O61) Seamless Low Finned Tube for Oil Cooler Pipe

| Brand | DALING Special Steel (DLSS) |

|---|---|

| Certificate | ABS, DNV.GL, LR, BV, NK, PED, AD2000, ISO, CCS, CRN, API |

| MOQ | 1PC |

| Delivery | 20 Days |

| Testing | HT, ET |

DALING SPECIAL STEEL, manufacturing and exporting Piping materials for more than 30 years, including Austenitic Stainless Steel, Super Duplex Steel, Nickel Alloy Steel (Hastelloy/Monel/Inconel/Incoloy), Copper and Copper Alloy Steel. DALING has the most advanced producing and testing equipments, our factory have been approved by: ABS, DNV.GL, BV, LR, NK, PED, AD2000, CCS, TS, ISO9001, ISO 14001, ISO18001, API, CRN No etc.

So far, more than 3200 companies from 56 countries trust us, such as Italy, UK, Germany, USA, Canada, Chile, Colombia, Saudi Arabia, Russia, Korea, Singapore, Australia, New Zealand, Poland, France etc, the count is increasing.

DALING is not just producer, we are more like problem solvers and focus on creating value for customers.

We can produce Copper Nickel 90/10 SB111 C70600-061 Low Finned Tube/Condenser Low Fin Tube. Our major grades including C70600 / C71500 / C12200 / C12100 / C68700 / C44300 etc.

Material Grade:

| Material Designation | Corresponding Material Symbol | ||||

| ASTM B111 | BS2871 | JIS H3300 | DIN1785 | GB/T 8890 | |

| Copper Nickel | C70600 | CN102 | C7060 | CuNi10Fe1Mn | BFe10-1-1 |

| C71500 | CN107 | C7150 | CuNi30Mn1Fe | BFe30-1-1 | |

| C71640 | CN108 | C7164 | CuNi30Fe2Mn2 | BFe30-2-2 | |

| C70400 | — | — | — | BFe5-1.5-0.5 | |

| — | — | — | — | B7 | |

| Aluminium Brass | C68700 | CZ110 | C6870 | CuZn20AL2 | HAL77-2 |

| Admiralty Brass | C44300 | CZ111 | C4430 | CuZn28Sn1 | HSn70-1 |

| Boric Brass | — | — | — | — | Hsn70-1B |

| — | — | — | — | Hsn70-1 AB | |

| Arsenical Brass | — | CZ126 | — | — | H68A |

| Brass Tube | C28000/C27200 | CZ108 | C2800/C2700 | CuZn36/CuZn37 | H65/H63 |

C70600 equals to BFe10-1-1 ; C71500 equals to BFe30-1-1

ASTM B111: Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

Quick Detail:

| General Low Fin Tubes Production Capacity | Specifications of Low Fin Tubes(‘N’ Fins) |

|

Finning Facility: 10 finning machines; Daily capacity up to 3000 meters; |

Tube OD: 12.7 mm~25.4mm Tube Length: 18 meters max. Fin Height: 1.2 mm ~2.77mm Fin Thickness: appr. 0.3mm Fin Pitch: 30 FPI /28 FPI/ 26 FPI/ 36 FPI /43 FPI |

Description:

Manufacturing process: The fins are rolled out of outer wall of the plain tubes by a pass roller. Tubes and fins are in same piece tube. We call it [N” fin type.

Delivery of Low Fin Tubes

We can produce the integral low fin tubes with un-finned section gaps( 5mm Min.) in the middle of core tube OR bent with designed Bend Radius.

Quality Test:

The integral low fin tube quality is assured by hydrostatic or pneumatic tests, eddy current tests & MARCO tests in order to verify design specifications.

Delivery Condition:

Tube ends are square cut, free burrs, internally dried and air blown clean, externally coated with varnish.

The desiccants are put into the each package for continental transportation.

Applications:

The Integral Low Finned Tubes find the preference in the following industrial sectors: