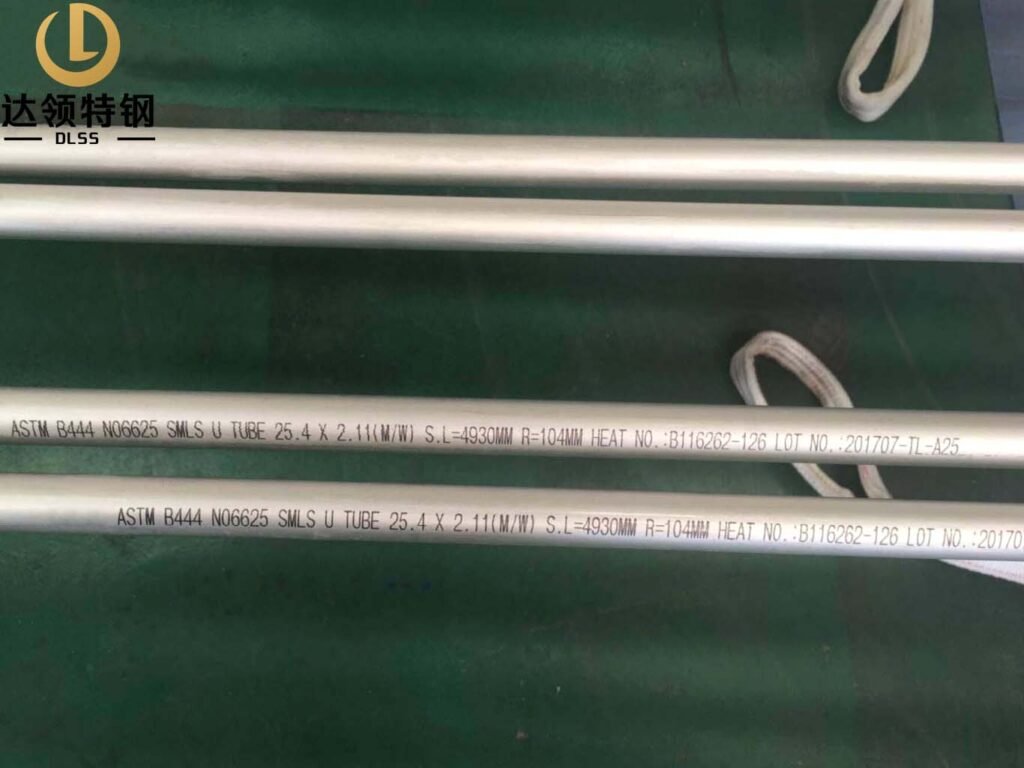

ASTM B444 GR.2 Inconel 625(N06625) Seamless U-bending Tube 25.4*2.11MW, Pickled Surface, ship to South Africa

| Brand | DALING Special Steel (DLSS) |

|---|---|

| Certificate | ABS, DNV.GL, LR, BV, NK, PED, AD2000, ISO, CCS, CRN, API |

| MOQ | 1PC |

| Delivery | ≥30 Days |

| Testing | HT, ET, UT |

DALING SPECIAL STEEL, manufacturing and exporting Piping materials for more than 30 years, including Austenitic Stainless Steel, Super Duplex Steel, Nickel Alloy Steel (Hastelloy/Monel/Inconel/Incoloy), Copper and Copper Alloy Steel. DALING has the most advanced producing and testing equipments, our factory have been approved by: ABS, DNV.GL, BV, LR, NK, PED, AD2000, CCS, TS, ISO9001, ISO 14001, ISO18001, API, CRN No etc.

So far, more than 3200 companies from 56 countries trust us, such as Italy, UK, Germany, USA, Canada, Chile, Colombia, Saudi Arabia, Russia, Korea, Singapore, Australia, New Zealand, Poland, France etc, the count is increasing.

DALING is not just producer, we are more like problem solvers and focus on creating value for customers.

Material Grade:

| Alloy | Alloy 200(N02200), Alloy 201(N02201), Alloy 20(N08020), Alloy 28(N08028), Alloy 31(N08031), Alloy 36 (K93600), Alloy 904(N08904) |

| Hastelloy | Hastelloy C22(N06022), Hastelloy C276(N10276), Hastelloy C4(N06045), Hastelloy S(N06635), Hastelloy C2000(N06200), Hastelloy G-30(N06030), Hastelloy G-35(N06035), Hastelloy X(N06002), Hastelloy N(N10003), Hastelloy B(N10001), Hastelloy B-2(N10665), Hastelloy B-3(N10675) |

| Monel | Monel 400(N04400), Monel 401 (N04401), Monel 404 (N04404), Monel K500(N05500), |

| Inconel | Inconel 600(N06600), Inconel 601(N06601), Inconel 617(N06617), Inconel 625(N06625), Inconel 690(N06690), Inconel 718(N07718), Inconel X-750(N07750) |

| Incoloy | Incoloy 800(N08800), Incoloy 800H(N08810), Incoloy 800HT(N08811), Incoloy 825(N08825), Incoloy 925(N08925), Incoloy 926(N09926) |

| Others | 253MA(S30815), 254SMO(S31254), S32304, 17-4PH(S17400), 17-7PH(S17700), 15-7PH(S15700) |

Inconel 625(N06625) Material has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Alloy625 has good oxidation resistance at temperature up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

Physical Properties:

| Density | 8.44 g/cm3 |

| Melting Range | 1290~1350℃ |

Size Range:

| Seamless Pipe | OD: Φ16mm-Φ114mm; WT:1.0mm-20mm |

| Welded Pipe | OD: Φ10mm-Φ273mm; WT:2mm-30mm |

Applications: